Robotics and automation

Robotics and automation

of production cells

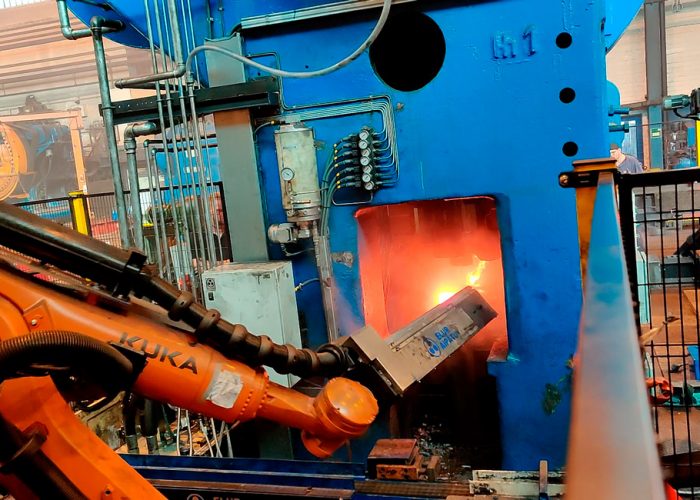

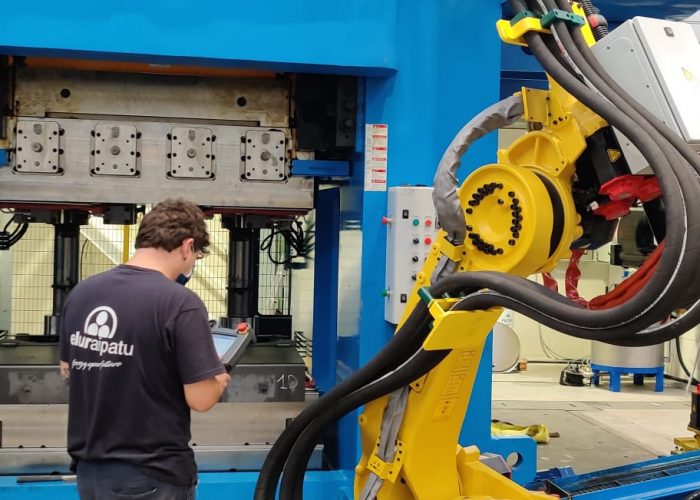

Elur Aipatu performs robotizations of hot forging processes

Analysing the process to be robotized: in addition to the computer tools, we can also avail ourselves of the valuable experience acquired in international projects

Adaptation of existing machines to the robotic process

Design and manufacture of machines and mechanisms that are necessary in the new process

Installation and programming of robots

Integral turnkey projects

The engineering department has a vast experience in programming the following equipment:

– PLCs: SIEMENS, OMRON, TEE, BECKHOFF.

– Robots: KUKA, FANUC y ABB

– SCADAS and custom software for the installation.

REMOTE DIAGNOSTICS

A technician can communicate with the equipment in the installation from any location on the planet in order to diagnose a possible fault or make program modifications.

REMOTE DIAGNOSTICS

A technician can communicate with the equipment in the installation from any location on the planet in order to diagnose a possible fault or make program modifications.